POLISHING THE PORTS AND CHAMBERS!

First things first, after evicting the carbon and junk from the ports and combustion chambers(if the machine shop bathing didn’t get it), rid all bumpy castings that would restrict the air flow in the exhaust ports. (Although irrelevant, you can see where the EGR system taps into the exhaust port for gases here. This was my first time seeing a 3SGTE head with EGR, kinda cool!)

I like to use the trusty "Mini-Dremel of Devine Porting" with a medium grinding stone that's beveled! This isn't an actual Dremel brand, just a skinny version from another company I bought in Japan. (It's alot cheaper than a Dremel too!) The famous Dremel has a tough time fitting in the ports with its larger size, plus it’s heavy and kinda over powered which could scratch things more than you want. *TIP: Wrap some tape around the metal moving parts that could scratch the aluminum head like shown!*

With a goose-neck lamp positioned like so, it makes it real easy to see what is going on inside the ports. Having some paper to cover the bulb helps to direct the light right into the head instead of in your face.  Generally, you don't want to enlarge the ports since that would just cause lower air velocities and hinder engine power. Just remove and blend away the casting bumps.

Generally, you don't want to enlarge the ports since that would just cause lower air velocities and hinder engine power. Just remove and blend away the casting bumps.  Using sandpaper and these sandpaper type grinders, try to blend everything out. Careful not to push too hard with the dremel tool, if the grinder piece is real rough,(especially with the strong wall outlet type Dremel) it will leave scratch marks that will be more difficult to remove than the pits and bumps in the head casting. This is where the light-weight dremel shines, it's nice and gentle.

Using sandpaper and these sandpaper type grinders, try to blend everything out. Careful not to push too hard with the dremel tool, if the grinder piece is real rough,(especially with the strong wall outlet type Dremel) it will leave scratch marks that will be more difficult to remove than the pits and bumps in the head casting. This is where the light-weight dremel shines, it's nice and gentle.

Next, buff things out a bit with this spinning scotch-brite piece. This is a good tool to use to see how the surface is looking.

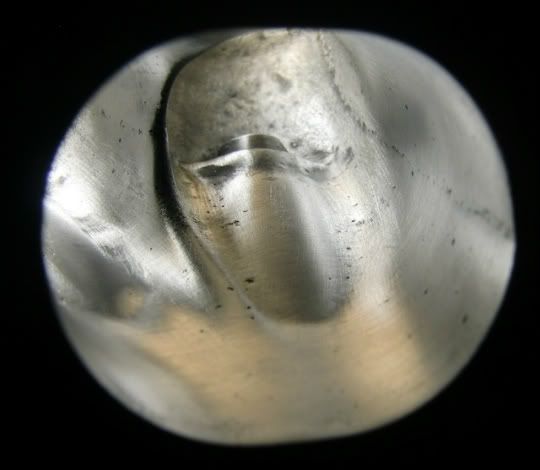

Next, buff things out a bit with this spinning scotch-brite piece. This is a good tool to use to see how the surface is looking.  It will look like this when done, which took less than 15mins, start to finish. And is all that's really needed to get the air flowing!

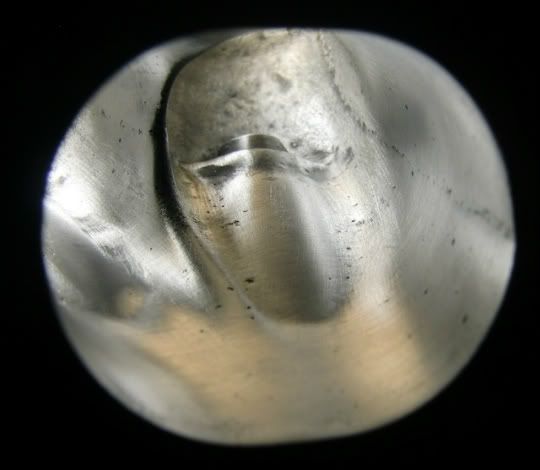

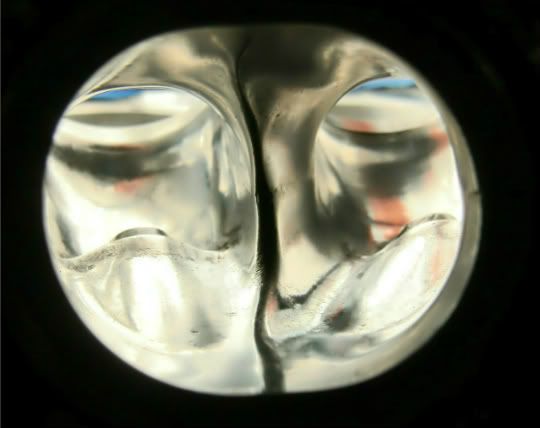

It will look like this when done, which took less than 15mins, start to finish. And is all that's really needed to get the air flowing!  You could spend more time trying to get rid of the remaining casting pits, but it'll take way more time, like double! Plus you still got all the rest to do... This is all you really need to get the most air flow going while providing some surface roughness to help mix up the air/fuel. However, this is the exhaust side, so make it shiny, to prevent carbon build up! Work your way up with finer sandpaper (after 600grit and you should be good, but wet sanding with 1000grit is even smoother: how much effort are you willing to put?) Do the polishing part last, after all the sanding is done on all ports and chambers (cause it will get scratched up again).

You could spend more time trying to get rid of the remaining casting pits, but it'll take way more time, like double! Plus you still got all the rest to do... This is all you really need to get the most air flow going while providing some surface roughness to help mix up the air/fuel. However, this is the exhaust side, so make it shiny, to prevent carbon build up! Work your way up with finer sandpaper (after 600grit and you should be good, but wet sanding with 1000grit is even smoother: how much effort are you willing to put?) Do the polishing part last, after all the sanding is done on all ports and chambers (cause it will get scratched up again).

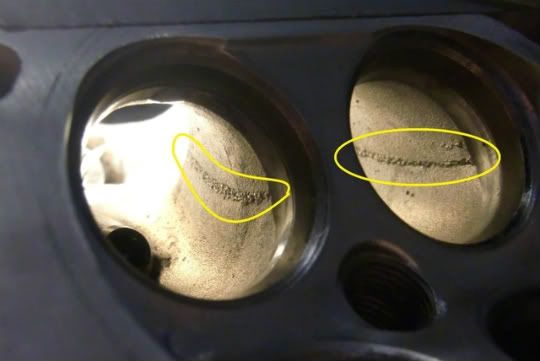

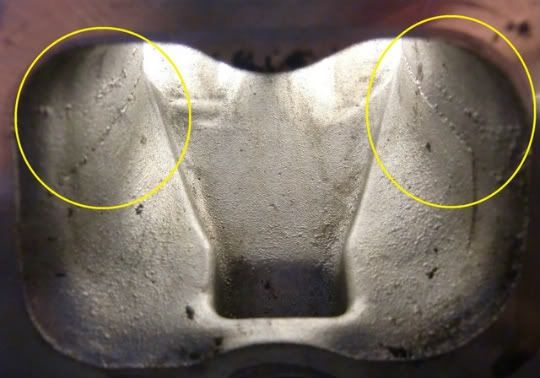

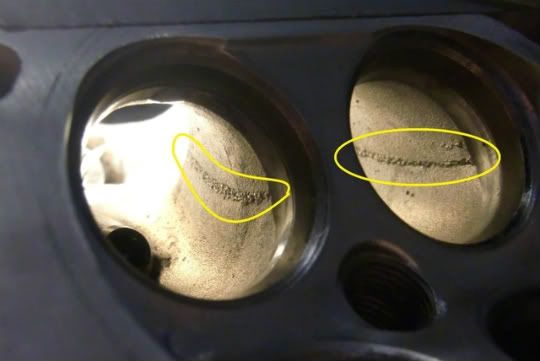

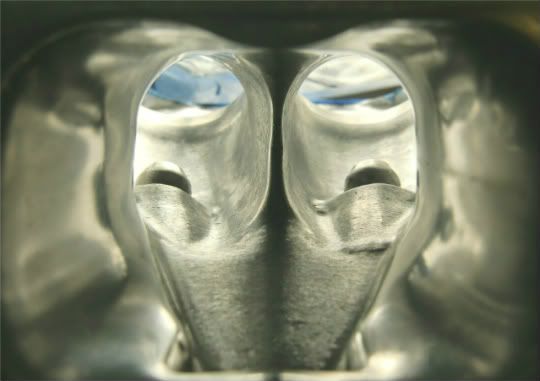

Now to work on the other end, from the combustion chamber side. More bumpy castings!

Grind and blend away those bumps on the exhaust and intake side, but be real careful not to scatch up the valve seats where the valves seal against or it is GAME OVER!

Try not to take away from the part just below the intake valve seats where it gets slightly narrow! This little part is a venturi and creates an area of higher air velocity for the intake port so it can cram and stuff that tight chamber with a huge load! Of air/fuel that is!!

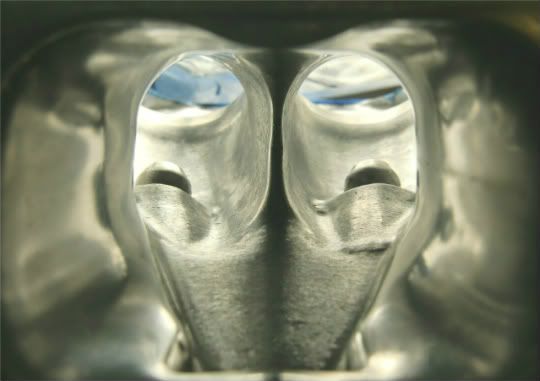

Now work the other end of the intake port where the injectors sit and blend away at the bumps!

The mini-dremel has great reach! Repeat the process just like for the exhaust ports.

Now for the combustion chamber area! I remember the gen3 motor not having these valve seats poking out... They were smooth from the start.

This really isn't a problem for the average motor, but I went ahead and ground away the sharp edges here on the valve seats. These, and any other high & pointy spots, are what can get real hot and cause unwanted detonation if the combustion chambers were pushed hard enough. They can act like mini glow-plugs. Careful again not to scratch the seats, as well as the head's surface!!! Tape up the head's surface so it is protected and prevents particles from getting inside.

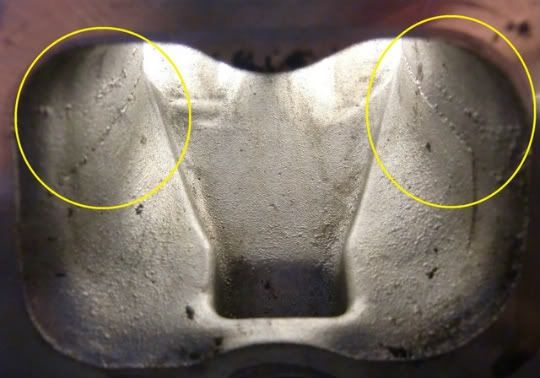

Now everything is flush with no pointy spots to get hot!

Now go to town with different grits of sandpapers and stuff to get the surface smooth! *TIP: Using the old unwanted valves to cover the rings will keep’m shielded from accidental scratches!!*

Buff out the surface with the scotch-brite tool again!

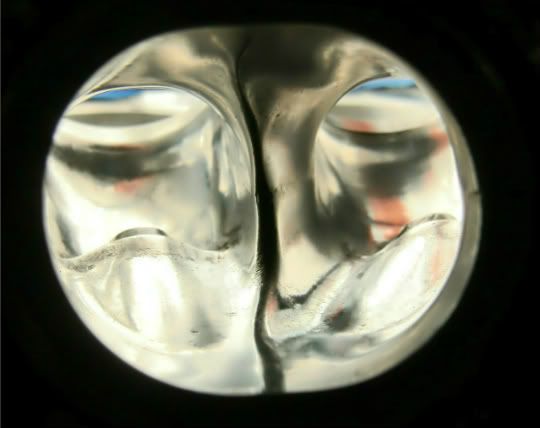

Now to polish everything with some polishing compound and some type of polish tip! This is my favorite part!  Polish the exhaust ports to make it slick so carbon won't build as easy! I use 2 different polishing compounds. A slighty rougher 1 first, then a more fine finishing compound next.

Polish the exhaust ports to make it slick so carbon won't build as easy! I use 2 different polishing compounds. A slighty rougher 1 first, then a more fine finishing compound next.  Then lastly, the intake ports! Leave a light rough finish after the injector if you want things to mix better. This was gently done with the 60grit grinder to leave a rough finish where the scratch marks are perpendicular to the air flow to help get the air rolling, and therefore mixing!

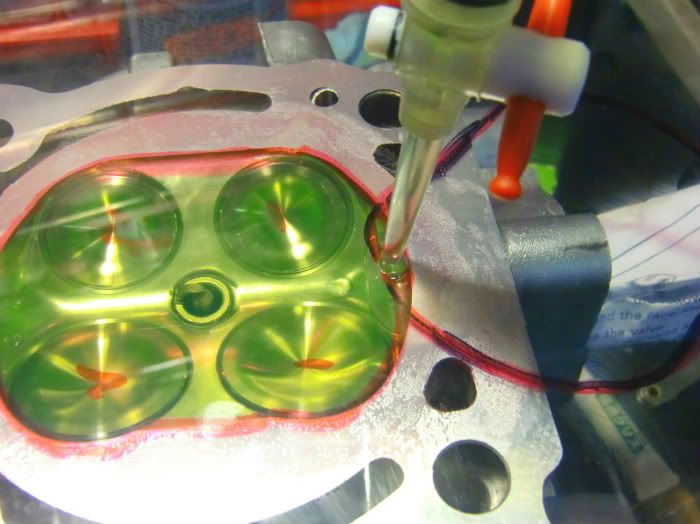

Then lastly, the intake ports! Leave a light rough finish after the injector if you want things to mix better. This was gently done with the 60grit grinder to leave a rough finish where the scratch marks are perpendicular to the air flow to help get the air rolling, and therefore mixing!  Lastly is to polish up the chambers! *TIP: Clean up the left over compound and polishing wheel peach-fuzz using lint-free micro-fiber clothes!* Don’t forget to clean out the valve guides too.

Lastly is to polish up the chambers! *TIP: Clean up the left over compound and polishing wheel peach-fuzz using lint-free micro-fiber clothes!* Don’t forget to clean out the valve guides too.  It would have been nice to port match but I am still deciding on which intake and exhaust parts to mate up with the head. So that will be skipped for now. Does anyone have any input on the T-VIS eliminating phenolic spacer???

It would have been nice to port match but I am still deciding on which intake and exhaust parts to mate up with the head. So that will be skipped for now. Does anyone have any input on the T-VIS eliminating phenolic spacer???

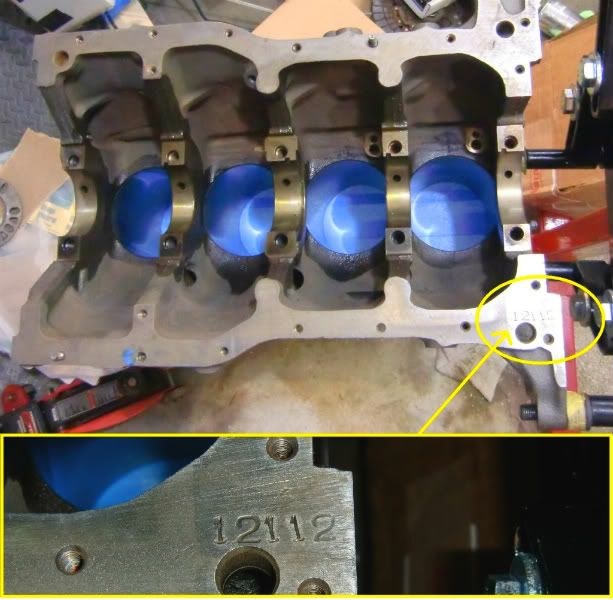

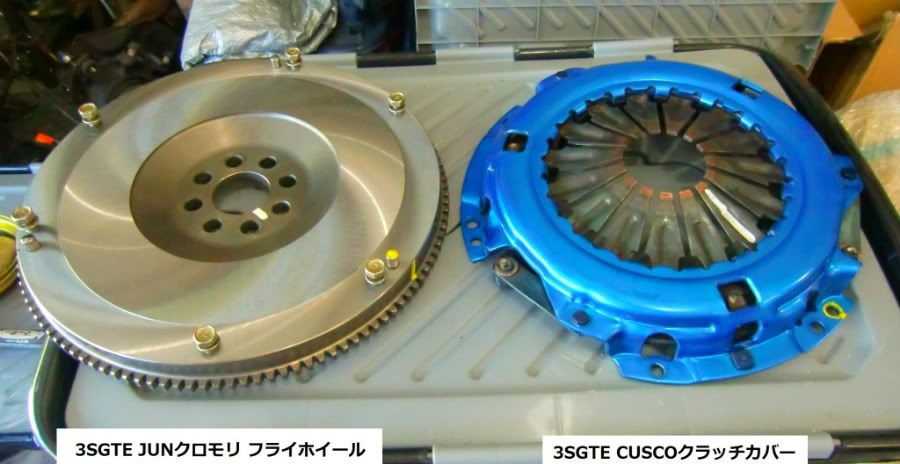

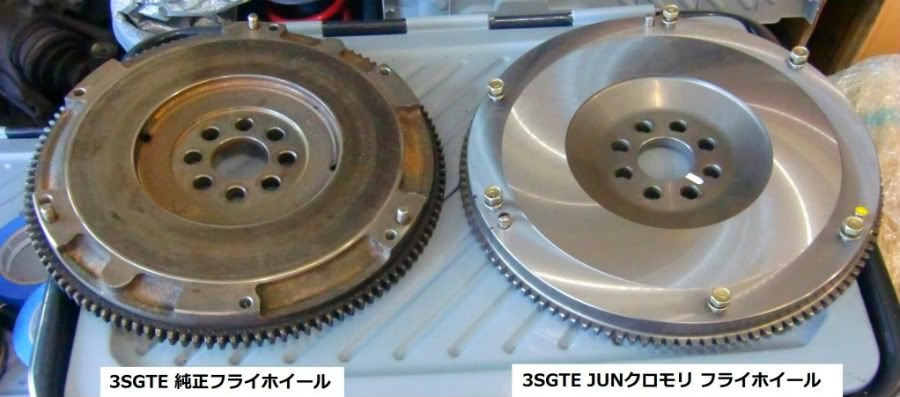

For now, it's time to take the head and block, along with the crank, flywheel, clutch, rev4 cams, and pistons & rods to ADAM'S METALIZING AND GRINDING to get machined and balanced!

Next Pg: https://minkara.carview.co.jp/userid/1308078/blog/24179169/

Back to Pg-1: https://minkara.carview.co.jp/userid/1308078/blog/24157663/ Posted at 2011/10/16 10:42:59 | |

トラックバック(0) | クルマ